Craft Business Direct Marketing Computers & Us Custom Cabinetry

DRIVING FORCES AND PARTNERS

Tomorrows Heirlooms was born in 1982 as the vehicle for me to grow in several areas important to me. First, it allowed me to exercise my entrepreneurial gene more than was possible within the large corporate culture of P&G. Next, it was a great way to develop my woodworking craft which started for me as a young boy working in my dad's millwork business under the watchful eye of Pennsylvania Dutch cabinetmakers. There is no greater challenge or reward than having other people value your work by paying for it. It was also a way to learn every functional aspect of business from marketing (demand creation), customer development and creative design, production and quality control, purchasing, and finance. Finally, it was a great excuse to add new equipment to my shop by designing each subsequent project around increased capability.

The key enabling factors that allowed Tomorrows

Heirlooms to operate successfully for 10 years were most certainly Blake and

Joyce. I started working with Blake when he was 15 as I was going through

my divorce and

Joyce was a terrific partner through the entire

endeavor. Our first shop

meeting for me to show him our Jewelry Boxes. As a result of her

initiative, we went from local trade shows to National distribution. Joyce

is the one who found our current house by searching for properties with

outbuildings suitable for the shop. Only setting up the laundry room took

precedence over building the new shop. I'm glad I was able to build two

kitchens and various pieces of furniture for Joyce to repay some of her

tolerance and partnership.

meeting for me to show him our Jewelry Boxes. As a result of her

initiative, we went from local trade shows to National distribution. Joyce

is the one who found our current house by searching for properties with

outbuildings suitable for the shop. Only setting up the laundry room took

precedence over building the new shop. I'm glad I was able to build two

kitchens and various pieces of furniture for Joyce to repay some of her

tolerance and partnership.

power tools. Our first project together was a kid sized workbench

made from an extra shelf from a bookcase project. At first, their help was

minimal but important. Later, Scott in particular became a frequent helper

in installations of new kitchens especially when it came to putting on the

hardware.

power tools. Our first project together was a kid sized workbench

made from an extra shelf from a bookcase project. At first, their help was

minimal but important. Later, Scott in particular became a frequent helper

in installations of new kitchens especially when it came to putting on the

hardware.

FROM "CRAFT" BUSINESS TO NATIONAL DISTRIBUTION

The business evolved in an interesting way

without benefit of any great strategy or business plan. We started with

mass production of a couple of models of cherry Jewelry Boxes that I had

designed and made as

The artwork and printing cost of the catalogue along with the

100% markup of the distributor and high labor cost for the boxes encouraged me

to try direct marketing of a simpler product with an innovative twist.

Ceramic rod knife sharpeners were new on the market and pretty popular and

expensive. I combined the rods with a sleek design cherry knife block into

an integrated system called "the best knife sharpener on the

block". I had read a lot of books on direct marketing so I proceeded

to hire an advertising agency to help me develop my first direct mail vehicle which was a classified add in Bon Appetit. To everyone who ordered

a knife block, I would enclose the catalogue page for a Jewelry Box with the

shipment. We needed a credit card account and lots of packaging and trips

to UPS. This venture was moderately successful, but the high

cost of ad placement made it very difficult to get a satisfactory

return.

vehicle which was a classified add in Bon Appetit. To everyone who ordered

a knife block, I would enclose the catalogue page for a Jewelry Box with the

shipment. We needed a credit card account and lots of packaging and trips

to UPS. This venture was moderately successful, but the high

cost of ad placement made it very difficult to get a satisfactory

return.

PR AND THE VALUE OF RELATIONSHIPS

This is where I learned about the power of free media via

PR. The food editor for USA Today was a personal friend. She agreed

to feature my block in the paper and to send press kits to food editors across

the  country

who look for things like this as "fillers". Over many months I received

many times the orders as the expensive ad with a new flurry with each placement

in regional newspapers. I have been a fan of free media and the value of

personal relationships in business ever since.

country

who look for things like this as "fillers". Over many months I received

many times the orders as the expensive ad with a new flurry with each placement

in regional newspapers. I have been a fan of free media and the value of

personal relationships in business ever since.

The business was started at the dawn of the PC age. In

the first year I used to lug home from P&G the earliest of the

"portable" computers...a Compaq with built in monochrome display and 51/4 floppy drive (no hard

drive). I wrote a program using visicalc to do all the accounting and

mailing label creation. Our first purchased computer was a IBM PS2 with a

20meg hard drive....I thought I had died and gone to heaven. I used

Lotus123 to write a program for generating cut lists for custom cabinetry.

This capability enabled me to do essentially all the design work in a single

weekend that would keep Blake busy for 6 weeks. Cabinet design software

(evolved to a higher level than my early version) is now common place in the

industry.

Compaq with built in monochrome display and 51/4 floppy drive (no hard

drive). I wrote a program using visicalc to do all the accounting and

mailing label creation. Our first purchased computer was a IBM PS2 with a

20meg hard drive....I thought I had died and gone to heaven. I used

Lotus123 to write a program for generating cut lists for custom cabinetry.

This capability enabled me to do essentially all the design work in a single

weekend that would keep Blake busy for 6 weeks. Cabinet design software

(evolved to a higher level than my early version) is now common place in the

industry.

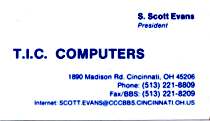

A terrific collateral benefit flowed from my dependence on,

and appreciation for computers. Scott showed great interest and

demonstrated exceptional talent by writing his first program in basic language

when he was just 8. He was encouraged and mentored by my brother-in-law

Tom, who provides IT support for Champion Paper. With the addition of an

800 baud modem to our PC, Scott never looked back.  He

started a computer bulletin board called "The Imperial Chapter" where

he and his friends could play games on line. Later, he started his own

business selling a hi-tech modem along with assorted peripherals. Today,

Scott is a program manager at Microsoft in Seattle, and I continue to push the

boundaries of my own computer capabilities and look for new ways to employ the

technology both at home and at P&G. Who knows if any of this would

have happened without the need to generate cut lists for Tomorrows Heirlooms.

He

started a computer bulletin board called "The Imperial Chapter" where

he and his friends could play games on line. Later, he started his own

business selling a hi-tech modem along with assorted peripherals. Today,

Scott is a program manager at Microsoft in Seattle, and I continue to push the

boundaries of my own computer capabilities and look for new ways to employ the

technology both at home and at P&G. Who knows if any of this would

have happened without the need to generate cut lists for Tomorrows Heirlooms.

Even though the mail order business was progressing, I decided

to shift emphasis to custom designed cabinetry. The business was turning

into a production operation with my role becoming more like a manager than an

innovator. I wanted to work directly with customers and design one of a

kind pieces that stretched my capability as a craftsman while increasing the

value of each sale. I started with a classified ad in the local![]() magazine. Our first few jobs were simple bookcases or entertainment

centers and mantles. Our first kitchen was my own in Hyde Park. Then

my boss at P&G asked me to do all the cabinetry for a large new house he was

building. This got me connected with a quality builder who asked me to

participate in Homerama with him the next year. The following year, we did

the cabinetry for another Homerama house built by my tennis partner. From

then on, we always had several months of backlog orders just through word of

mouth. Many of these jobs were for P&G people.

magazine. Our first few jobs were simple bookcases or entertainment

centers and mantles. Our first kitchen was my own in Hyde Park. Then

my boss at P&G asked me to do all the cabinetry for a large new house he was

building. This got me connected with a quality builder who asked me to

participate in Homerama with him the next year. The following year, we did

the cabinetry for another Homerama house built by my tennis partner. From

then on, we always had several months of backlog orders just through word of

mouth. Many of these jobs were for P&G people.

I was pretty successful at evolving the work to a higher level of custom design with each new customer. This enabled increased pricing and profitability as well as an excuse to add new equipment along the way. I took pictures of many of these jobs which I used to help new customers with design ideas. I have some of the pictures in a photopoint album accessible by this link WEB ALBUM OF CUSTOM CABINETRY EXAMPLES

END OF THE ERA

The success of the business actually led to my decision to cease operations in 1992. We reached a point where I was either going to have to hire additional help for Blake; or stop altogether. Since gearing up would need to be supported by even greater demand, I would have had to commit even more of my free time to customer development and design and I didn't have any left. At the same time, my role at P&G was becoming even more demanding and from an "earning a living" standpoint, was the clear choice. My only real concern was for Blake. Luckily, he was able to continue working with the contractor we had often used to help with kitchen installations. Blake still works with him remodeling basements and kitchens and as I write this, Blake is out back in my shop building cabinets for one of his relatives.

All is well that ends well. I must admit that I had no idea that people had so much free time as I discovered after the last job was completed. I now have a shop that makes Norm's "New Yankee Workshop" look like amateur land and I can switch on the lights and build pieces for my own family whenever I choose. And who knows, what special cowboy designs I might dream up when Joyce and I move to Colorado.